Continuous Improvement Network Continuous Improvement Network Logo Design

Traditional process improvement techniques like Six Sigma, Lean and Kaizen have enabled the successful transformation of innumerable companies over the last few decades.

Even though they are based on a scientific approach to improve processes and increase the quality of the output, their relevance has decreased considerably. In fact, as effective as they were in the past, they are critically flawed for delivering the same impactful change moving forward without additional, new solutions.

The Need for Faster and More Integrated

Our world has changed radically since the beginning of the century. All elements of the modern enterprise are highly dynamic, complex and require high speed. Companies nowadays rely on elaborate processes, driven by global networks that provide resources, skills, and inputs to satisfy the demand of audiences dispersed around the globe. Take for instance, bringing to market a smartphone. For a smartphone to meet minimum consumer standards, the solution must have a tight integration between its operating system, hardware, software, user communities, etc. Each of these components is created by distributed networks, who must find a way to integrate seamlessly in the eyes of the customer. It is no longer feasible to consider each area independently and expect a major improvement in overall performance if changed.

In contrast, conventional process improvement techniques typically work well when things are relatively stable and are localized (say a manufacturing plant), but react very slowly in more dynamic environments (say integrating Uber Eats' supply chain). Each technique – control charts, process mappings, etc. – was designed to analyze a specific, localized area and maximize its efficiency. So, if you have a product that interfaces with the market, the implementation of concurrent, independent process improvements may not converge.

An Emerging Science: What is Network-Based Process Analytics?

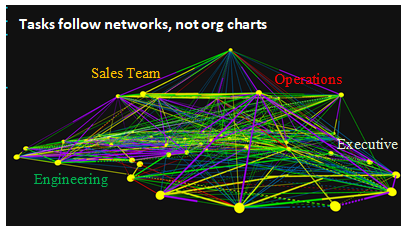

Network analytics arose from the perspective that organizations work around issues, tasks, and activities – not processes or organizational charts. Thus, the basic building blocks of an organization's effectiveness are individual, day-to-day interactions between people. These interactions happen within networks of decision and influence, large and small, operating within teams, between departments, and across the entire company, even across partner companies. These networks tend to take on a life of their own – and often they have little to do with the formal organizational structure and, in many cases even the documented processes.

An easy way to understand network analysis is to realize that organizations work just like the human brain. If neurons do not connect effectively, then your brain will spend more effort to perform a given task. Similarly, if people (the organization's neurons) are not integrated properly, the result is inefficient processes and lower than optimal organizational performance.

An easy way to understand network analysis is to realize that organizations work just like the human brain. If neurons do not connect effectively, then your brain will spend more effort to perform a given task. Similarly, if people (the organization's neurons) are not integrated properly, the result is inefficient processes and lower than optimal organizational performance.

A solid Network Analysis methodology provides a structured approach for achieving performance uplift. It should give management visibility to understand fundamental elements in an organization to make meaningful changes:

- Communication networks: Examines the flow of information across the organization in the processes under study

- Influence networks: How individuals influence decisions and activities within the organization. It provides visibility of the influence level of each stakeholder in the process

- Decision networks: Studies the networks that drive core decisions. This proves the misconception that it is the CEO or the Big Boss have the final word in day to day decisions

Rethinking Process Engineering

Process improvement methodologies identify waste (or non-value add) and value add activities. The idea is to stop activities that are a waste and redeploy those resources toward activities that produce value. Thus, to be effective, tools must quickly identify, diagnose, design and synthesize processes in situations with a high order of complexity.

The traditional way to look at a company is through the lens of the organizational chart, with its hierarchies, "dotted lines" and other forms of structure but is this the way people perform their work?

According to Dr. Michael Mann, "An organization that is thought to operate in accordance with its formal org chart – DOESN'T." This is because enterprises are dynamic and organize around tasks, not charts. Also, when performing tasks people will gravitate toward the path of least resistance, not what is most efficient and productive for the company. Therefore, if we are going to make enterprise-wide improvements, we must recognize that processes, tasks, and people are highly dynamic.

Network Analytics are Organizational MRIs

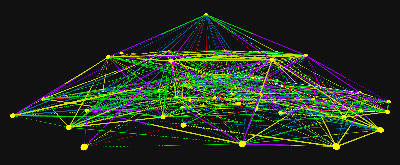

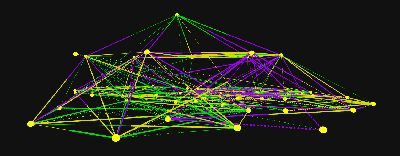

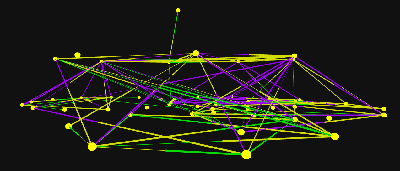

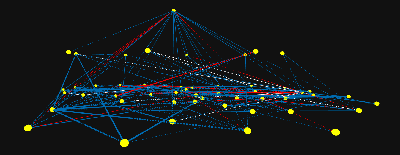

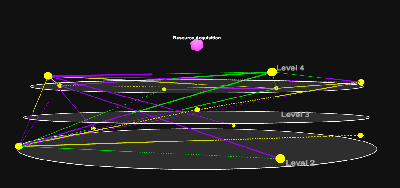

Network analytics is the equivalent of taking an MRI inside the organization: you need accurate instruments and the ability to interpret their results. Let's explore a few scenarios to understand how processes can be improved drastically through the aid of such tools. The processes below are examples captured using Argonaut™, a leading organizational network analytics tool. In these examples, the 3D diagrams, lines show actual interactions between people in an organization, their frequency (thickness) and the perceived importance associated with such interactions (color). You will also notice that in several instances, a line leaves a node with a specific thickness and a color, but connects to a different node in a different thickness or color. This is a documented disagreement between stakeholders and therefore a sign of process pathology.

All Interactions | Enterprise processes can be very complex. Interactions between consequential stakeholders vary in frequency, importance and agreement levels. There is organizational noise; deeper analysis is required to understand the opportunities for improvement. |

High-Frequency, High-Importance – Disagreed | High Frequency, High Importance disagreements display areas that require attention. High Frequency and Importance typically means that at least one party is spending significant effort to push a task forward. When this is not reciprocated, it yields waste. |

High-Frequency, High-Importance – Agreed | High Frequency, High Importance agreements are the tasks that everybody agrees makes the organization move forward. In a restructuring, these are the key areas that must remain undisturbed. |

High-Frequency Low-Importance – Agreed | Agreed Low Important interactions are in brief, misallocated efforts. Everybody agrees that such tasks do not add significant value, but are done following an empty process ritual. Stop doing them, especially the ones with High Frequency. |

Emergence View™: Identifying influencers and decisions makers | In a network Emergence View, what "emerges" at higher levels are the real decision makers and their degree of influence, regardless of organizational rank. These are the people who get the job done (or not!) as nominated by their peers. |

As-Is, Should-Be, As-Of

The application of network analysis should not be a one-time shot. An "As-Is" study performed at the beginning and allows management to understand the current state and therefore gain an order of magnitude estimate for required changes. This should be complemented with a "Should-be" assessment by stakeholders based on their unique perspective in the organization. The target state is a negotiated agreement that takes the As-Is and the Should-Be.

"As-of" analyses provide an objective state of the processes under study as of a given date and allows you to objectively measure progress. As-of's are performed throughout the life of change process to ensure that the organization is making progress as planned. In addition to being a very effective tool to monitor the pace of change, it allows management to correlate improvements in company processes with the desired outcomes.

Key Benefits of Using Network Analysis in Process Improvement

In a fast-changing business environment, we need to look for new tools to make process improvement effective. Network analysis is becoming a key component of organizational process management in the 21st century as it blends processes, people, and their interrelations. Understanding and addressing such complexities can improve speed to market, innovation and turn monolithic processes into major organizational weapons. As important, it helps to ensure that any network analysis goes beyond the superficial "social network" and connects the true interactions that result in actions taken by company personnel and other decisions regarding resource allocation.

Process improvements will result in the following three areas:

- Alignment to the Business. Are processes typically aligned to where the largest payoffs would be? The reality is that most process improvements methods do not even think about creating a repeatable link to creating business value. Network analysis can provide management with continuous visibility to identify where the largest payoffs will be – and monitor their progress. As shown above, management can perform an "MRI" of consequential organizational processes and visually identify the areas that need the most attention. As important, a broader study would also point out if the support systems are performing their function aligned to the key business drivers.

- Recognize invisible connections with external processes. Enterprise processes are highly interactive and connected. They are dynamic and have interdependent interfaces. This is, if you make changes to a process, it will have a cascading effect on other processes, typically causing disruptions. Network analysis allows you to look at the system holistically: identify the process you are planning to improve, and it will tell you what the areas in the company that you need change at the same time are. You will get this information FAST without weeks of endless classic process mapping and stakeholder interviews.

- Anticipate outcome before all changes are implemented. Network analysis gives you a simple tool to monitor the process of change, and therefore you can make near-time interventions. By identifying the links that need to be created, changed or decommissioned, you can create a specific change plan and monitor how each change affects the outcome. This is a fundamental departure from classic process improvement initiatives. By employing techniques such as As-is, Should-be, and As-of, you monitor the process change, not the end state of change, thereby giving management ample opportunities to make tactical course corrections as needed.

About the Authors

Dr. Mann is the Chairman of Creso Global, an international consulting practice applying the latest insights from neuroscience, behavioral economics, and best-practice project management. He has served as an advisor to corporations and government agencies around the globe, including the United Nations; as the CEO of a diversified high technology company with industrial, commercial, service, and aerospace business units; as the founder of successful engineering, manufacturing, and service arms; as an outside director of both public and closely held high technology and health services companies; as a member of the Board of Examiners of the Malcolm Baldrige National Quality Award; and on the Army Science Board, where he chaired the Directed Energy and Ballistic Missile Defense panels. Email: [email protected]

Dr. Mann is the Chairman of Creso Global, an international consulting practice applying the latest insights from neuroscience, behavioral economics, and best-practice project management. He has served as an advisor to corporations and government agencies around the globe, including the United Nations; as the CEO of a diversified high technology company with industrial, commercial, service, and aerospace business units; as the founder of successful engineering, manufacturing, and service arms; as an outside director of both public and closely held high technology and health services companies; as a member of the Board of Examiners of the Malcolm Baldrige National Quality Award; and on the Army Science Board, where he chaired the Directed Energy and Ballistic Missile Defense panels. Email: [email protected]

Erich Kreidler, Managing Partner of KRE Consulting, has more than two decades of organizational consulting, management, and leadership experience. Erich, who heads KRE's Project Management and Operations practice, is recognized for his expertise and experience in integrating complex organizations to generate optimal results; helping organizations scale for rapid growth; and the development of responsible and responsive crisis management processes. Kreidler lectures at USC's Viterbi School of Engineering at the graduate level and has also served as a panelist, moderator and keynote speaker for several industry conferences and summits. Erich is also a founding member

and president-emeritus of the Institute of Industrial Engineers, Orange County, California Chapter. Email: [email protected]

Erich Kreidler, Managing Partner of KRE Consulting, has more than two decades of organizational consulting, management, and leadership experience. Erich, who heads KRE's Project Management and Operations practice, is recognized for his expertise and experience in integrating complex organizations to generate optimal results; helping organizations scale for rapid growth; and the development of responsible and responsive crisis management processes. Kreidler lectures at USC's Viterbi School of Engineering at the graduate level and has also served as a panelist, moderator and keynote speaker for several industry conferences and summits. Erich is also a founding member

and president-emeritus of the Institute of Industrial Engineers, Orange County, California Chapter. Email: [email protected]

sullivanhungs1936.blogspot.com

Source: https://www.batimes.com/articles/the-evolution-of-six-sigma-continuous-improvement-using-network-analysis/

0 Response to "Continuous Improvement Network Continuous Improvement Network Logo Design"

Post a Comment